Understanding 3D Printable Gears

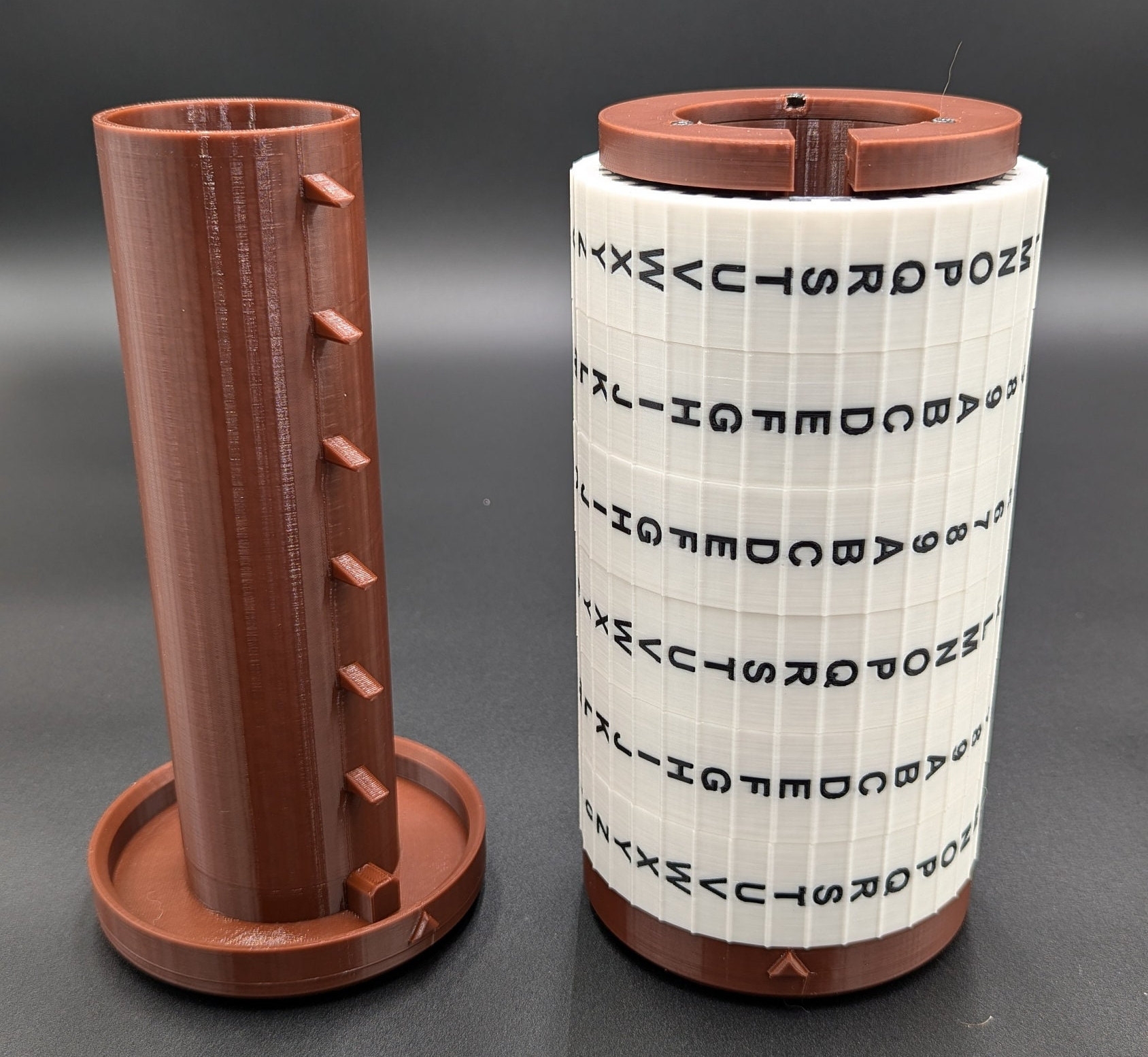

The world of 3D printing has revolutionized countless industries, and one of the most fascinating applications is the creation of gears. But what exactly are 3D printable gears, and why are they gaining so much traction in 2024? Simply put, these are gears designed to be manufactured using 3D printing technology, also known as additive manufacturing. Unlike traditional methods like machining or molding, 3D printing builds the gear layer by layer from a digital design. This opens up a whole new realm of possibilities in terms of complexity, customization, and material choices. Think about it: you can create gears with intricate internal structures, optimize their geometry for specific load requirements, and even use materials tailored to withstand extreme temperatures or corrosive environments. The beauty of 3D printable gears lies in their flexibility. Whether you’re a hobbyist tinkering in your garage, an engineer prototyping a new product, or a manufacturer looking to reduce costs, these gears offer a compelling solution. Furthermore, the accessibility of 3D printing technology means that you don’t need to invest in expensive machinery or specialized tooling to produce high-quality gears. All you need is a 3D printer, some filament, and a well-designed digital model. The impact of this technology extends beyond just the manufacturing process. It’s fostering innovation, empowering individuals to create their own solutions, and driving the development of new and exciting products. As 3D printing technology continues to evolve, we can expect to see even more advanced applications of 3D printable gears, making them an indispensable tool for designers, engineers, and makers alike.

The Benefits of Using 3D Printed Gears

So, why should you consider using 3D printed gears instead of traditional methods? The advantages are numerous and compelling. First and foremost is the ability to create highly customized gears. With traditional manufacturing, creating a unique gear design can be expensive and time-consuming, often requiring specialized tooling and expertise. However, 3D printing allows you to produce gears with complex geometries and specific performance characteristics without the added cost and delay. Imagine designing a gear with a unique tooth profile to optimize torque transfer or creating a lightweight gear with internal support structures to reduce inertia. 3D printing makes all of this possible. Another significant benefit is the speed of prototyping. Traditional gear manufacturing can take weeks or even months, but 3D printing allows you to create prototypes in a matter of hours. This rapid prototyping capability is invaluable for designers and engineers who need to test and refine their designs quickly. You can iterate through multiple versions of a gear, making small adjustments each time, until you achieve the perfect fit and performance. Furthermore, 3D printing offers a wider range of material options compared to traditional methods. You can use materials like ABS, PLA, nylon, PETG, and even more exotic materials like carbon fiber reinforced composites to create gears that meet your specific requirements. This flexibility allows you to tailor the gear’s strength, durability, and resistance to environmental factors. For example, you might use a high-temperature nylon for a gear that needs to operate in a hot environment or a carbon fiber composite for a gear that needs to be lightweight and strong. Finally, 3D printing can be a more cost-effective solution for low-volume production runs. The upfront cost of setting up a traditional gear manufacturing process can be significant, but with 3D printing, you can produce small quantities of gears without the need for expensive tooling. This makes it an ideal option for startups, hobbyists, and anyone who needs to create a small number of custom gears.

Choosing the Right Material for Your 3D Printed Gears

Selecting the appropriate material is crucial for ensuring the performance and longevity of your 3D printed gears. The choice depends on a variety of factors, including the intended application, the load requirements, the operating temperature, and the environmental conditions. Let’s delve into some of the most popular materials for 3D printed gears and their respective strengths and weaknesses. PLA (Polylactic Acid) is a biodegradable thermoplastic that is widely used in 3D printing due to its ease of use and low cost. It’s a good choice for prototyping and non-critical applications where strength and heat resistance are not paramount. However, PLA is relatively brittle and has a low glass transition temperature, meaning it can soften and deform at relatively low temperatures. ABS (Acrylonitrile Butadiene Styrene) is another popular thermoplastic known for its higher strength and heat resistance compared to PLA. It’s a good choice for gears that need to withstand higher loads and temperatures. However, ABS is more prone to warping during printing and requires a heated bed and enclosure for best results. Nylon is a strong and durable thermoplastic with excellent wear resistance and a low coefficient of friction. It’s a good choice for gears that need to withstand repeated use and abrasion. However, nylon is hygroscopic, meaning it absorbs moisture from the air, which can affect its printing properties and mechanical properties. PETG (Polyethylene Terephthalate Glycol-modified) is a glycol modified version of PET. It offers a good balance of strength, flexibility, and ease of printing. It also has good chemical resistance. It is a good all-around choice for gears where you need a material stronger than PLA but easier to print than ABS or Nylon. For more demanding applications, you might consider using materials like carbon fiber reinforced composites or high-performance polymers like PEEK or Ultem. These materials offer exceptional strength, stiffness, and heat resistance, but they also require specialized 3D printers and printing expertise. Ultimately, the best material for your 3D printed gears will depend on your specific needs and requirements. It’s important to carefully consider the pros and cons of each material before making a decision.

Designing for Success

Designing 3D printable gears requires a different approach than designing gears for traditional manufacturing methods. There are several key considerations to keep in mind to ensure that your gears are strong, durable, and easy to print. One of the most important factors is the orientation of the gear during printing. The orientation affects the strength of the gear teeth and the overall print quality. In general, it’s best to orient the gear so that the teeth are printed vertically, with the build plate perpendicular to the gear axis. This maximizes the strength of the teeth and minimizes the need for support structures. Another important consideration is the use of support structures. Support structures are necessary to support overhanging features during printing, but they can also be difficult to remove and can leave behind unsightly marks. It’s important to minimize the need for support structures by carefully orienting the gear and designing it with self-supporting features. For example, you can use angled surfaces or chamfers to reduce the overhang angle and eliminate the need for supports. The infill pattern and density also play a significant role in the strength and weight of the gear. A higher infill density will result in a stronger gear, but it will also increase the weight and printing time. A lower infill density will result in a lighter gear, but it will also be weaker. The choice of infill pattern can also affect the strength and stiffness of the gear. For example, a rectilinear infill pattern is strong in one direction, while a gyroid infill pattern is strong in all directions. Finally, it’s important to consider the limitations of your 3D printer. Different 3D printers have different capabilities in terms of resolution, accuracy, and material compatibility. It’s important to design your gears within the capabilities of your printer to ensure that they are printed successfully.

Applications of 3D Printed Gears

The applications of 3D printed gears are incredibly diverse, spanning across various industries and fields. One of the most common applications is in robotics. Custom gears are often needed for robotic arms, drivetrains, and other mechanisms. 3D printing allows you to create gears with specific sizes, tooth profiles, and materials to optimize the performance of your robot. Whether you’re building a small hobby robot or a large industrial robot, 3D printed gears can provide a cost-effective and flexible solution. Another area where 3D printed gears excel is in prototyping. As mentioned earlier, the ability to quickly create prototypes is invaluable for designers and engineers. 3D printing allows you to test different gear designs and materials without the need for expensive tooling or long lead times. This can significantly accelerate the product development process and help you bring your products to market faster. 3D printed gears are also finding increasing use in custom machinery and equipment. Many industries require specialized machines that are not available off-the-shelf. 3D printing allows you to create custom gears and other components to build these machines to your exact specifications. This can be particularly useful in industries like manufacturing, agriculture, and aerospace. Furthermore, 3D printed gears are being used in repair and maintenance applications. When a gear breaks in a machine, it can be difficult and expensive to find a replacement. 3D printing allows you to create a replacement gear quickly and easily, minimizing downtime and saving money. This can be particularly useful for older machines where replacement parts are no longer readily available. Finally, 3D printed gears are becoming increasingly popular in hobbyist and DIY projects. Whether you’re building a clock, a model car, or a kinetic sculpture, 3D printed gears can provide a fun and creative way to add motion to your projects. The possibilities are endless, and the only limit is your imagination.

3D Printable Gears

This exploration has detailed the functionality, benefits, material considerations, and design principles associated with 3D printable gears. Additive manufacturing offers unique advantages in terms of customization, rapid prototyping, and the creation of complex geometries, expanding design possibilities beyond traditional manufacturing limitations. Material selection, dependent on the intended application’s demands, remains critical for achieving optimal performance and longevity in these components.

The evolution of materials science and additive manufacturing technologies will undoubtedly further enhance the capabilities and applications of 3D printable gears. Continued research and development are essential to address existing limitations and unlock the full potential of this transformative manufacturing approach, paving the way for wider adoption across diverse engineering disciplines. Further investigation into advanced polymers and composite materials specifically tailored for additive processes promises to significantly improve the strength, durability, and efficiency of additively manufactured gears.